When Safety and Strength Matter

There are two types of heat-treated glass: heat-strengthened and fully tempered. Wolverine Glass produces both types of heat-treated glass which can be used monolithically, laminated, or as part of an insulated glass unit. Only fully tempered glass will meet the ANSI Z97.1 and CPSC 16 CFR 1201 test requirements for use in glazing hazardous locations.

Heat-Strengthened Glass

Heat-strengthened glass, which is much stronger than annealed glass, has a large break pattern, making it less likely to vacate the opening upon breakage. Though it does not meet the safety impact glazing requirements, it is used frequently in areas where glass fall-out is a concern.

Features

- Available in a broad range of glass types

- Thicknesses from 1/8″ (3 mm) up to 1/2″ (12 mm)

- Min. size: 10″ x 10″

- Max. size for 1/8″ (3mm) glass: 40″ x 80″

- Max. size for 5/32″ (4mm) up to 1/2″ (12mm) glass: 96″ x 198″

- Two times stronger than annealed glass

- Meets ASTM C 1048 surface compression requirements

- Large break pattern preventing fall-out

- Resist thermal and mechanical shock

- Should not be used in safety glazing applications

- Hole size options and placement will vary based on glass thickness

- Can be used monolithically or insulated

Applications

Non-safety rated vision areas

Laminated glass

Spandrel glass for non-vision areas

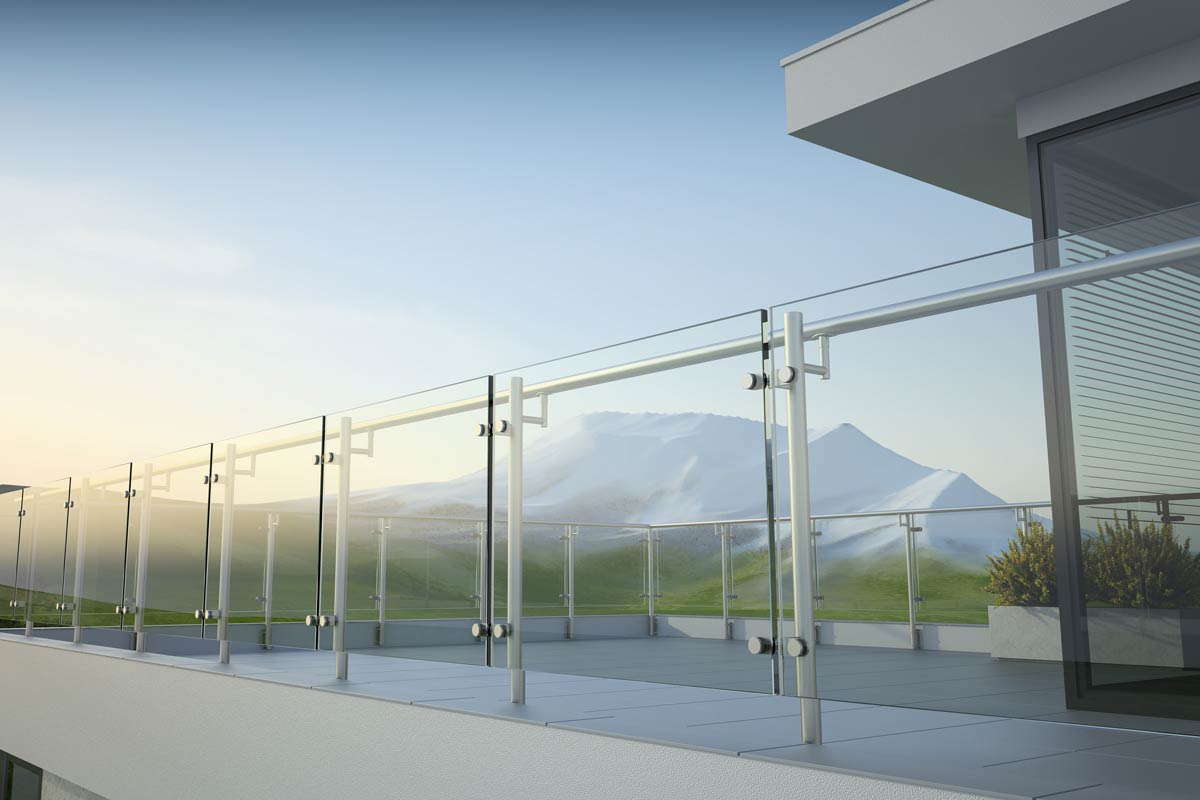

Tempered Glass

Tempered glass, also referred to as ‘fully tempered,’ is heated to approximately 1,112⁰ F (600⁰C) and rapidly cooled, which seals the surface of the glass into a state of compression. Upon impact, tempered glass shatters into small fragments, significantly reducing the level of harm that might otherwise occur with annealed glass. Resistant to mechanical and thermal stresses, tempered glass is a safety glazing solution that is up to five times stronger than annealed glass.

Features

- Available in a broad range of glass types

- Thicknesses from 1/8″ (3 mm) up to 3/4″ (19 mm)

- Min. size: 10″ x 10″

- Max. size for 1/8″ (3mm) glass: 40″ x 80″

- Max. size for 5/32″ (4mm) up to 3/4″ (19mm) glass: 96″ x 198″

- Meets ASTM C 1048 surface compression level requirements

- Upon impact will break into small fragments

- Thermal and mechanical shock resistant

- Tested and approved by the Safety Glazing Certification Council (SGCC) to meet ANSI Z97.1 / CPSC 16 CFR 1201 and CAN/CGSB standards for safety glazing

- Hole size options will vary based on glass thickness

- Can be used monolithically or insulated

Applications

All glass entrances

Automotive

Display cases

Doors and sidelites

Furniture

Glass partitions

Shelving

Shower enclosures

Smoke baffles

Store fixtures

Storefronts and curtain walls

Windows